In today’s competitive business landscape, efficient warehouse management goes far beyond simply tracking inventory. Modern warehouses face increasing pressure to maximize every square foot while maintaining operational efficiency. This is where advanced Warehouse Management Systems (WMS) come into play – transforming traditional storage facilities into optimized, data-driven operations centers.

Introduction: The Evolution of Warehouse Space Management

The days of managing warehouses with clipboards and spreadsheets are firmly behind us. As e-commerce continues to surge and customer expectations for fast delivery intensify, businesses are realizing that efficient space utilization is directly tied to profitability. A well-implemented WMS doesn’t just count inventory – it transforms how space is conceptualized, allocated, and utilized throughout the warehouse ecosystem.

Space Planning and Optimization: The Foundation of Warehouse Efficiency

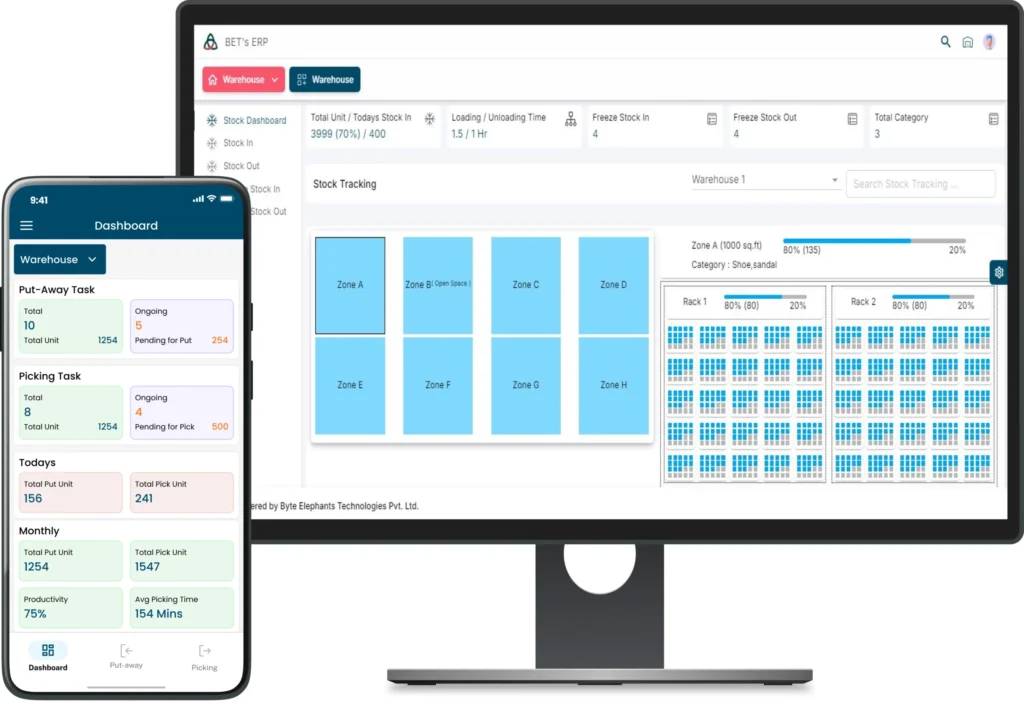

Warehouse Space Management Tools

Modern WMS platforms offer sophisticated tools for designing and optimizing warehouse layouts. These tools utilize spatial algorithms to create digital twins of the physical warehouse, allowing managers to visualize and simulate different configurations before implementing them.

Advanced systems can analyze historical data patterns to recommend optimal layouts based on:

- Product velocity (how quickly items move through the warehouse)

- Order profiles (which products are frequently ordered together)

- Seasonal fluctuations in demand

- Physical characteristics of products (size, weight, handling requirements)

This data-driven approach ensures that warehouse layouts evolve with business needs rather than remaining static over time.

Dynamic Slotting: Responsive Space Allocation

Perhaps one of the most powerful features of modern WMS is dynamic slotting – the ability to automatically or manually adjust storage locations based on real-time conditions. Unlike traditional warehouses where products remained in fixed locations, dynamic slotting continuously optimizes product placement.

For example, during holiday seasons when certain products experience dramatic increases in demand, the WMS can automatically recommend relocating these items to prime picking locations to reduce travel time and improve efficiency. This responsive approach ensures that warehouse space allocation remains optimized even as business conditions change.

Key benefits of dynamic slotting include:

- Reduced picker travel time

- Improved ergonomics by placing frequently accessed items at optimal heights

- Better space utilization as seasonal items rotate through premium locations

- Reduced congestion in high-traffic areas

Inventory and Storage Management: Maximizing Every Cubic Foot

Zone Management :

Effective WMS implementations divide warehouses into logical zones based on strategic criteria. This zoning approach allows for specialized handling processes tailored to product characteristics or operational requirements.

Common zoning strategies include: :

- Velocity-based zones (fast-moving vs. slow-moving products)

- Temperature-controlled zones for sensitive items

- Security zones for high-value merchandise

- Special handling zones for hazardous materials or fragile items

- Forward pick areas vs. bulk storage areas

By implementing zone-specific processes, warehouses can optimize both space utilization and operational efficiency simultaneously.

Bin and Rack Management :

At a more granular level, WMS solutions track and manage individual storage locations – bins, racks, and shelves – ensuring optimal placement and accessibility. Advanced systems maintain detailed profiles of each storage location, including:

- Exact dimensions and weight capacity

- Current inventory levels and remaining capacity

- Accessibility requirements (equipment needed to reach items)

- Environmental conditions (temperature, humidity, etc.)

This detailed tracking allows the system to make intelligent decisions about where to place incoming inventory, considering not just available space but compatibility with location characteristics.

Space Utilization Monitoring :

Real-time monitoring of space utilization metrics helps warehouse managers identify inefficiencies and opportunities for improvement. Modern WMS dashboards typically display metrics such as:

- Shelf space occupancy percentages

- Empty bin counts

- Underutilized zones

- Congested areas

This visibility enables proactive space management rather than reactive firefighting when space constraints become critical.

Barcode-Based Material Handling: Streamlining Space Utilization

Automated Barcode Generation :

BETs WMS solutions automate the barcode generation process, creating unique identifiers for each batch of finished goods received from SAP. These barcodes contain critical information, including:

- Product identification

- Batch/lot numbers

- Production dates

- Expiration information

- Physical characteristics

This detailed encoding enables more intelligent space allocation decisions, as the system can consider product-specific requirements when assigning storage locations.

Barcode Scanning for Real-Time Tracking

Barcode scanning technology transforms how warehouse personnel interact with inventory and space. By scanning items as they move through the warehouse, the WMS maintains real-time visibility into:

- Exact location of every item

- Current status (received, stored, picked, packed, shipped)

- History of movements

- Handler information (who performed each action)

This granular tracking eliminates the space inefficiencies caused by “lost” inventory – items that physically exist in the warehouse but can’t be located due to poor record-keeping.

Material Movement Tracking

The WMS tracks material movement throughout the warehouse lifecycle, from receiving through storage and picking to shipping. This continuous monitoring ensures optimal space utilization at each stage:

- Receiving: Immediate identification of appropriate storage locations

- Storage: Verification that items are placed in their designated locations

- Picking: Confirmation that correct items are retrieved

- Shipping: Validation that orders are complete and accurate

By minimizing errors in material handling, the WMS reduces the space inefficiencies associated with misplaced items, incorrect picks, and returns processing.

Put-Away and Pick-Up: Optimizing Warehouse Traffic Patterns

Optimal Put-Away Strategies

Put-away processes significantly impact warehouse space utilization. Advanced WMS algorithms suggest the most efficient storage locations for new inventory based on multiple factors:

- Available space dimensions

- Product characteristics

- Expected storage duration

- Frequency of access

- Proximity to related items

These sophisticated algorithms balance immediate space efficiency against future operational efficiency, recognizing that the “cheapest” put-away decision (in terms of immediate time/effort) might create downstream inefficiencies.

Efficient Pick-Up Processes

Similarly, pick-up processes are optimized to reduce travel time and enhance picking efficiency. The WMS can generate pick lists that:

- Group items by zone to minimize travel between areas

- Sequence picks to create efficient routes through the warehouse

- Batch similar orders to reduce redundant travel

- Consider equipment requirements to minimize equipment changes

By optimizing these movement patterns, warehouses can operate efficiently with higher inventory density, as less space needs to be dedicated to movement paths and staging areas.

Task Assignment and Verification

The WMS facilitates structured task assignment, allowing managers to generate and assign specific put-away and pick tasks to individual employees. This accountability ensures that space utilization plans are executed as designed rather than being subject to ad-hoc decisions by warehouse staff.

Error prevention features, such as verification scans, ensure that items are placed in or retrieved from correct locations. If an employee attempts to put away an item in the wrong location, the system generates an alert requiring approval before proceeding. This prevention of location errors maintains the integrity of the warehouse space allocation plan.

Completion Notifications and Metrics

Task completion notifications provide real-time visibility into warehouse operations, allowing managers to monitor progress and redistribute resources as needed. The system also captures important metrics like task completion times, which can be analyzed to identify bottlenecks and opportunities for layout improvements.

Real-Time Space Monitoring: Anticipating Constraints Before They Occur

Space Availability Tracking

Perhaps one of the most valuable aspects of modern WMS is the ability to monitor available space in real-time. Rather than discovering space constraints during receiving operations, managers can see exactly how much capacity remains:

- Overall warehouse capacity utilization

- Zone-specific availability

- Individual rack or bin availability

- Special storage area status (temperature-controlled, high-security, etc.)

This visibility enables proactive space management, allowing teams to reorganize, consolidate, or expedite outbound shipments before space constraints become critical.

Capacity Alerts and Notifications

Automated alerts notify warehouse managers when space utilization approaches predefined thresholds. These early warnings might indicate:

- Overall facility approaching capacity limits

- Specific zones becoming congested

- Particular product categories requiring additional space

- Seasonal storage areas needing expansion

By providing advance notice of potential space constraints, the WMS enables managers to implement mitigation strategies before operations are impacted.

Analytics: Data-Driven Space Optimization

Comprehensive Utilization Reporting

Modern WMS solutions provide detailed analytics on space utilization across multiple dimensions:

- Zone-specific utilization rates

- Product-category space consumption patterns

- Seasonal space requirement fluctuations

- Storage efficiency by product type

These reports help identify inefficient space allocation patterns that might not be obvious through daily operations. For example, analytics might reveal that certain slow-moving products consistently occupy premium picking locations, or that particular zones are chronically under-utilized.

Operational Efficiency Metrics

Beyond simple space utilization, WMS analytics connect space management to broader operational efficiency metrics:

- Cycle time analysis (how quickly items move through the warehouse)

- Picking accuracy rates

- Labor efficiency by zone or activity

- Cost-per-order metrics

These insights help warehouse managers understand the relationship between space allocation decisions and operational performance, enabling data-driven optimization.

Insightful Dashboards

Visual dashboards translate complex space utilization data into actionable insights. Modern WMS dashboards typically feature:

- Heat maps showing warehouse congestion patterns

- Trend analyses of space utilization over time

- Predictive models forecasting future space requirements

- Benchmark comparisons against industry standards or historical performance

These visualization tools help managers quickly identify opportunities for space optimization that might be missed in traditional spreadsheet reports.

Conclusion: The Future of Warehouse Space Optimization

As warehousing continues to evolve, WMS solutions are becoming increasingly sophisticated in their approach to space optimization. Emerging technologies like artificial intelligence, machine learning, and IoT sensors are being integrated into WMS platforms to further enhance space utilization.

The reality is clear: in today’s competitive business environment, efficient warehouse space utilization is no longer optional – it’s essential for survival and growth. A well-implemented WMS delivers the tools, data, and processes needed to transform warehouse space from a fixed constraint into a strategic advantage.

By adopting a comprehensive approach to warehouse space optimization – from initial layout planning through real-time monitoring and continuous improvement – organizations can accommodate growing inventory demands without proportional increases in facility size or operating costs. In an era where warehouse space is at a premium and customer expectations continue to rise, this capability isn’t just an operational improvement – it’s a competitive necessity.