Quality control isn’t just a checkbox—it’s the backbone of manufacturing business sustainability. One manufacturing company learned this lesson the hard way when a seemingly minor oversight in raw material quality control spiraled into a financial disaster. Let’s explore how proper Quality control software like BETs Quality control software can prevent such catastrophes and transform quality from a cost center to a competitive advantage.

When Quality Control Fails: A Cautionary Tale

Imagine this scenario: A mid-sized manufacturing company receives a shipment of raw materials i.e flavouring agent. Pressed for time and operating with manual quality checks, the team skips through its inspection. The materials move directly into production.

For an entire month, the factory operates at full capacity, transforming these defective raw materials into finished products. Unaware of the lurking problem, the company proudly ships these goods to various customers. Then, the complaints begin pouring in.

Products are failing in the field. Customer satisfaction plummets. After thorough investigation, the company traces the issue back to that single batch of defective flavouring agent that entered production without proper quality checks.

The consequences? The company must buy back all products manufactured during that month—a direct financial hit of millions rupees. But the real damage extends far beyond this immediate loss. Brand reputation, customer trust, and future business opportunities all suffer immeasurable damage.

All this because a quality check worth a few minutes and rupees was overlooked.

How to Prevent Quality Control Disasters

The above scenario isn’t just a hypothetical cautionary tale—it’s a reality many manufacturers face. The good news? Modern Quality Control software systems like BETs Quality control software are specifically designed to prevent such disasters through systematic quality management.

The Rule of Quality Control Software: Three Critical Checkpoints

1. Raw Material Quality Control (RM QC)

The first line of defense in quality management is thorough raw material inspection. Proper RM QC involves:

- Systematic sampling procedures for incoming materials

- Predefined acceptance criteria for each raw material

- Digital documentation of test results

- Supplier performance tracking through Vendor Management System.

With digital Quality Control software like BETs Quality Control software, these processes become standardized, leaving no room for human error or skipped steps. The system simply assists production not to begin with substandard materials.

2. Finished Goods Quality Control (FG QC)

Even with perfect raw materials, manufacturing processes can introduce quality variations. Finished goods QC serves as your last opportunity to catch defects before they reach customers:

- Comprehensive testing against product specifications

- In Process QC

- Statistical process control to identify drift before it becomes problematic

- Digital quality certificates for every batch

- Integration with inventory systems to prevent shipping of unreleased products

Modern QC systems enforce these checks and provide real-time visibility into quality metrics across production batches.

3. Batch Tracking and Traceability

When quality issues do arise, the ability to quickly trace affected products can mean the difference between a minor correction and a catastrophic recall:

- Complete genealogy of each product batch

- Raw material to finish good traceability

- Production parameter documentation

- Automated identification of affected batches when issues arise

- Quick isolation capabilities for suspect inventory

This traceability doesn’t just minimize damage during quality incidents—it provides valuable data for continuous improvement initiatives.

BETs QC: Comprehensive Quality Management System

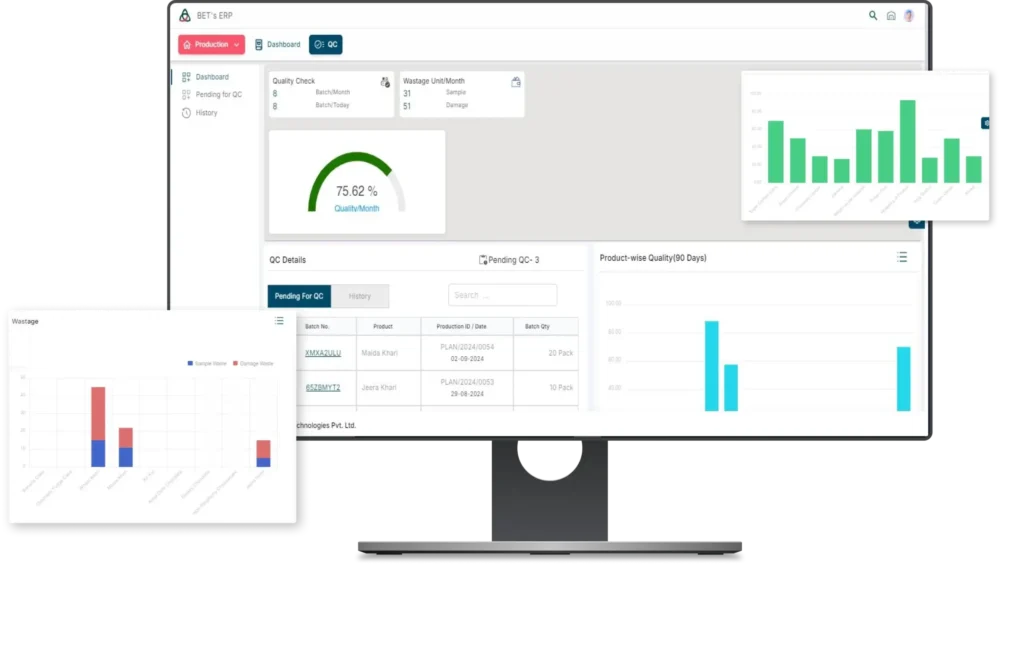

BETs Quality Control software represents the cutting edge in manufacturing quality control software, offering end-to-end quality management capabilities designed for both compliance and operational excellence.

Key Features of BETs QC :

- Digital Workflows: BETs Quality Control software replaces paper-based systems with digital workflows that enforce proper testing sequences and documentation.

- Real-Time Analytics: Quality trends become visible before they become problems through comprehensive dashboards and alerts.

- Integration Capabilities: BETs Quality Control software connects with Vendor Portal, Production Module, WMS, and other systems to create a seamless information flow.

- Compliance Documentation: Automatic generation of compliance documents saves time while ensuring regulatory requirements are met.

- Supplier Quality Management: Extended quality control reaches back into the supply chain for truly comprehensive quality assurance.

Benefits Beyond Disaster Prevention

While preventing scenarios like our cautionary tale is certainly valuable, BETs Quality Control software delivers additional benefits that transform quality from a cost center to a competitive advantage:

Operational Excellence :

- Reduced Rework: Catching issues early minimizes expensive rework.

- Higher Yield: Consistent processes lead to better material utilization.

- Faster Release Cycles: Automated testing and documentation speeds time to market.

- Data-Driven Improvements: Quality analytics inform process optimization.

Financial Impact :

- Lower Quality Costs: Prevention costs a fraction of what remediation requires.

- Reduced Inventory Holding: Confidence in quality allows for leaner inventory levels.

- Higher Price Points: Consistent quality justifies premium pricing.

- Customer Retention: Quality consistency builds valuable long-term relationships.

Competitive Advantage :

- Brand Reputation: Quality excellence becomes a market differentiator.

- Regulatory Compliance: Staying ahead of evolving quality requirements.

- Supplier Relationships: Data-driven supplier management improves upstream quality.

- New Market Access: Meeting stringent quality standards opens doors to premium markets.

The Economics of Quality: A Closer Look

Let’s revisit our cautionary tale with a deeper economic perspective. The raw materials that caused the disaster may have cost just a few thousand rupees, but the cascading financial impact reached 25 lakhs—a multiplier effect of nearly 100x.

This dramatic amplification effect is common in quality failures: :

- Direct Costs: Product buyback, replacement, shipping

- Operations Costs: Investigation time, production reschedules, overtime

- Market Costs: Discounting to rebuild customer confidence, lost sales

- Long-term Costs: Damaged reputation, increased customer acquisition costs

The investment in a comprehensive QC system like BETs Quality Control software typically represents less than 5% of these potential losses while virtually eliminating the risk of such catastrophic failures.

Conclusion: From Quality Control to Quality Commitment

The shift from traditional quality control to comprehensive quality management systems like BETs Quality Control software represents more than just technological advancement—it signals a fundamental change in how manufacturers view quality.

Quality is no longer just about inspection; it’s about prevention. It’s not just about meeting specifications; it’s about continuous improvement. And perhaps most importantly, it’s not just about avoiding costs; it’s about creating value.

The manufacturing company in our example learned a painful 25 lakh lesson that a simple raw material inspection could have prevented. Their story serves as a reminder that in modern manufacturing, quality isn’t an expense—it’s your most important investment.

With BETs Quality Control, quality becomes more than a department or function—it becomes a company-wide commitment embedded in every process, decision, and product. In today’s quality-conscious market, that commitment may be your greatest competitive advantage.

Is your quality system preventing disasters or just documenting them? Contact BETs Quality Control today to transform your approach to quality management.