Picture this: You’re building a majestic stone arch—every block carefully shaped and placed to form a perfect curve. But there’s one critical element missing: the keystone. Without it, the entire structure is unstable, unsupported, and at risk of collapse. All your effort feels wasted, because without that one overlooked piece, the whole arch can’t stand.

This is exactly what happens to supply chain without a strong Vendor Management System (VMS).

That missing keystone? It’s the vital link that holds your supply chain arch together — the point where vendor coordination, communication, and control all converge. Without it, what should be a smooth, stable operation turns into a fragile structure—vulnerable to misalignment, delays, and disruption. BETs VMS fits right into that gap, locking everything in place and turning fragmented workflows into a unified, resilient supply chain.

A) What Happens When the Keystone is Missing from Your Supply Chain Arch?

In any well-functioning supply chain, every department — from procurement to production to distribution — relies on a delicate balance of timing, communication, and collaboration with vendors. The Vendor Management System (VMS) serves as the keystone in this arch, silently holding everything together. When it’s missing or inefficient, the entire structure becomes unstable. What starts as a small disconnect at the vendor level quickly spirals into major operational setbacks, ultimately stalling growth and damaging brand credibility.

Here’s how the absence of a strong VMS weakens each part of the business:

Production Suffers Delays & Downtime

- Inconsistent raw material availability due to poor visibility into vendor supply schedule

- Last-minute surprises lead to production halts and missed manufacturing deadlines

Inability to plan batches effectively, resulting in overproduction or shortages

Quality Takes a Hit

- Lack of vendor performance tracking means recurring quality issues go unnoticed

No centralized platform to manage QC checklists, certifications, or inspections

- Increased returns and rework due to defective or subpar inputs

Sales Teams Lose Their Edge

- Stock unavailability affects order fulfillment rates and customer satisfaction

- Sales forecasts become unreliable when upstream vendor data is missing

- Missed opportunities in high-demand periods due to disrupted supply

Distribution & Logistics Break Down

- Delays from vendors ripple into logistics planning and lead to missed dispatch schedules

No real-time coordination means higher transportation costs and inefficiencies

- Difficulty in route optimization or load planning due to erratic vendor timelines

Brand Reputation Suffers

- Inconsistent product quality and missed deliveries erode customer trust

- Lack of transparency makes it harder to uphold sustainability or compliance commitments

Retailers and distributors may start favoring more reliable competitors

Growth Slows Down

- Business leaders spend more time firefighting than scaling.

Vendor risks remain unmanaged, creating unpredictable operational bottlenecks

Expansion plans stall due to weak supply chain foundations

Without a VMS acting as the keystone of your supply chain arch, coordination turns into chaos, efficiency crumbles, and growth becomes a struggle. BETs VMS is designed to fill this critical gap — creating structure, enabling control, and ensuring your supply chain stands strong under pressure.

How BETs VMS Strengthens the Entire Business Operations & Growth

A Vendor Management System may seem like a backend utility, but when designed with depth and foresight—like BETs VMS—it becomes a catalyst for operational excellence. Here’s how it adds value across critical functions of a business:

1. Streamlines Production Management

- Seamless PO & Schedule Sync between ERP and vendors ensures timely delivery of materials, aligning vendor supplies directly with production schedules.

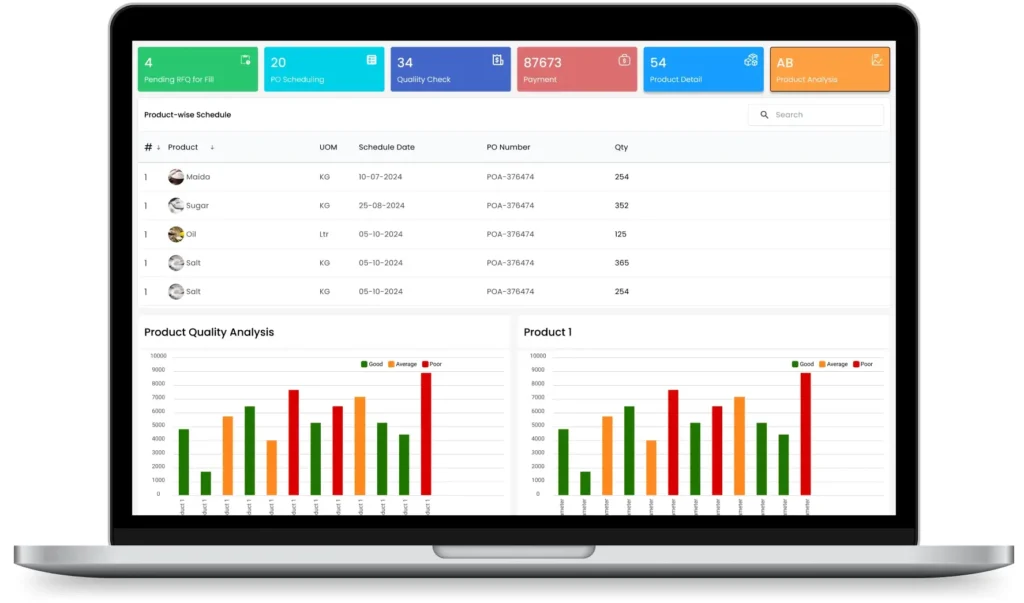

- PO Tracking Dashboards & Auto PO Sharing allow production planners to stay ahead of vendor delays and adjust plans proactively.

- Rejection Management Sync ensures that production never proceeds with substandard materials, maintaining consistency in output.

Outcome: Smoother production flow, reduced idle time, and optimized resource planning.

2. Enhances Raw Material Inventory Control

- RFQ and Quotation Comparison Tools enable procurement teams to choose the most reliable and cost-effective vendors, ensuring consistent RM availability.

- Rate Contracts with Vendors stabilize pricing and support long-term inventory planning.

- Vendor Performance Dashboards help in identifying and eliminating suppliers who contribute to frequent stockouts or delayed deliveries.

Outcome: Reliable RM supply, cost control, and minimal overstocking or understocking.

3. Ensures Finished Goods Quality

- Integrated QC Process & Rejection Reports synced with ERP and shared with vendors enhance visibility and accountability.

- Quality Reports by Material/PO/Vendor provide actionable insights to the quality team for ongoing improvements.

- QR/Barcode-Based Vehicle Entry ensures only authorized, validated supplies enter the plant, reducing contamination or mix-ups.

Outcome: Fewer production defects, improved batch quality, and strengthened brand consistency.

4. Improves Distribution Accuracy

- Accurate Vendor Delivery Tracking and real-time PO status ensure dispatch schedules are planned precisely without last-minute changes.

- ERP-synced Billing and Order Details avoid errors during order picking, packing, and delivery.

- Rejected/Unloaded Material Tracking ensures defective raw materials don’t affect downstream operations like dispatch or replenishment.

Outcome: On-time deliveries, minimal errors, and improved coordination with warehouse & logistics teams.

5. Increases Sales Potential

- Fewer stockouts mean better fulfillment rates, which keep distributors and retail partners happy.

- Stable production cycles lead to more consistent product availability across regions.

- Reduced quality issues mean fewer returns, fewer complaints, and a more satisfied customer base.

Outcome: Better market coverage, enhanced distributor loyalty, and faster order-to-cash cycles.

6. Drives Business Growth

- Fewer stockouts mean better fulfillment rates, which keep distributors and retail partners happy.

- Stable production cycles lead to more consistent product availability across regions.

- Reduced quality issues mean fewer returns, fewer complaints, and a more satisfied customer base.

Outcome: Efficient operations, scalable processes, and a solid foundation for sustainable growth.

Why BETs VMS is the Right Choice for Your Organization

Built for Real-World Complexity

BETs VMS isn’t a theoretical solution built in isolation. It’s designed by professionals who understand the real-world challenges of supply chain management. Every feature addresses specific pain points that procurement teams face daily.

ERP Integration

One of the biggest concerns companies have when implementing new systems is the potential disruption to existing processes. BETs VMS addresses this concern head-on with its comprehensive ERP integration capabilities.

Scalability for Growth

Whether you’re managing 50 vendors or 5,000, the system scales seamlessly to accommodate your growth. The architecture supports multiple locations, currencies, and compliance requirements.

User-Friendly Design

Despite its comprehensive functionality, the system remains intuitive and easy to use. Vendors with limited technical expertise can navigate the portal effortlessly, while procurement professionals get the advanced analytics and control they need.

Continuous Innovation

The BETs team continuously enhances the system based on user feedback and industry trends. Your investment in VMS grows more valuable over time as new features and capabilities are added.

Conclusion: Completing Your Supply Chain Puzzle

Your supply chain is only as strong as its weakest link. Without a robust vendor management system, that weak link is often the disconnect between your organization and your vendors. BETs VMS provides the missing piece that transforms your fragmented vendor ecosystem into a cohesive, efficient, and transparent supply chain operation.

The question isn’t whether you need a vendor management system – it’s whether you can afford to continue operating without one. Every day without VMS is another day of inefficiencies, missed opportunities, and strained vendor relationships.

The complete picture of supply chain excellence is within reach. BETs VMS provides the missing piece that brings everything together, creating a seamless, efficient, and transparent vendor ecosystem that drives your organization’s success.

Ready to complete your supply chain puzzle? The missing piece is waiting for you.

Ready to transform your vendor management processes? Contact BETs today to learn how our comprehensive VMS solution can fill the operational gaps in your supply chain and drive unprecedented efficiency and transparency in your vendor relationships.