In today’s fast-paced logistics and manufacturing landscape, efficient warehouse management is critical to ensuring smooth operations, reducing overhead costs, and enhancing customer satisfaction. However, many mid-scale manufacturers and warehousing service providers still struggle with outdated or overly complex systems that limit their ability to adapt and scale effectively. This is where the BETs Mobile-Based Warehouse Management System (WMS) steps in—a revolutionary solution that brings cutting-edge technology to the fingertips of warehouse managers and operators.

Designed specifically for mid-plus scale manufacturers and warehousing service providers, this innovative WMS integrates the power of mobile devices with the flexibility and scalability needed for today’s dynamic supply chain demands. Unlike traditional systems that often require bulky hardware and extensive training, this mobile-first platform is intuitive, real-time, and highly customizable. It allows users to manage inventory, track shipments, and optimize warehouse operations directly from their smartphones or tablets—empowering teams to make quicker, data-driven decisions on the go.

This solution is uniquely positioned to bridge the gap between operational complexity and technological ease, providing a tailored approach to warehouse management that fits the specific needs of mid-tier businesses. Whether you’re optimizing storage space, improving order fulfillment, or reducing lead times, this mobile-based system is designed to keep your operations running at peak performance—anytime, anywhere.

Warehouse automation is the cornerstone of efficient supply chain management. BETs’ Mobile WMS integrates advanced technology to streamline and automate processes, reducing manual intervention and human errors. From inventory management to order fulfillment, every task is simplified, ensuring faster turnaround times and improved accuracy.

By incorporating intelligent features like movement optimization and space monitoring, the platform empowers businesses to reduce operational costs, increase productivity, and enhance overall efficiency. It’s not just about managing a warehouse; it’s about creating a smart, automated environment where every process works in harmony.

Why is WMS Necessary?

A Warehouse Management System (WMS) is essential for optimizing inventory handling, ensuring accurate stock management, and streamlining operations like picking, packing, and shipping. It enhances efficiency, minimizes errors, and provides real-time visibility into warehouse activities, helping businesses scale and adapt to dynamic market demands.

Challenges of Manual Operations:

- Inefficiency: Manual processes are time-consuming and prone to errors, leading to delays in order fulfillment.

- Stock Discrepancies: Lack of real-time inventory tracking often results in overstocking or stockouts.

- Poor Visibility: Limited transparency into warehouse operations affects decision-making.

- Human Dependency: Increased reliance on staff can lead to bottlenecks during peak demand or workforce shortages.

Features of BETs Mobile App-Based WMS

1. Auto Put Away & Pickup List

Efficiency begins with proper organization. The Mobile WMS automatically generates put-away and pickup lists, ensuring that materials and products are stored and retrieved with precision. By analyzing warehouse layouts and inventory data, the system assigns optimal locations for each item, minimizing the time spent on these tasks. This feature enhances operational speed and ensures that the warehouse remains organized at all times.

2. Barcode-Based Material Handling

Barcode-based material handling is a game-changer in maintaining inventory accuracy and ensuring FIFO (First In, First Out) or LIFO (Last In, First Out) compliance. By scanning barcodes, employees can quickly locate items, update stock records, and track movements. This reduces errors, prevents expired products from being shipped, and minimizes waste due to rejections or spoilage.

3. Employee Work Productivity Tracking

Understanding employee productivity is essential for optimizing labor resources. The Mobile WMS tracks individual and team performance by monitoring task completion times, accuracy, and overall efficiency. This data helps managers identify top performers, provide targeted training, and allocate resources effectively to meet peak demands.

4. Space Monitoring and Optimization

Space is a premium commodity in warehouses, and its efficient utilization can significantly impact costs and productivity. The Mobile WMS continuously monitors available space and suggests optimal arrangements for storage. By analyzing factors such as item size, frequency of retrieval, and storage conditions, it ensures maximum space utilization while maintaining easy access to frequently used items.

5. Movement Optimization

The platform leverages advanced algorithms to optimize movements within the warehouse. Whether it’s following FIFO, LIFO, or creating the shortest route for item retrieval, the system reduces travel time and fuel or energy costs for automated equipment. This feature enhances operational efficiency and ensures timely order fulfillment.

6. Accurate Stock Management

Accurate stock management is vital for maintaining smooth operations and customer satisfaction. BETs’ Mobile WMS provides real-time inventory updates, tracks stock levels, and identifies discrepancies. With precise data, businesses can avoid overstocking, understocking, and stockouts, ensuring optimal inventory levels at all times.

Smart Integration

Integration is crucial for businesses to maintain smooth operations, as it eliminates data silos and enables real-time data synchronization across various systems. This connectivity ensures that all departments work with the most up-to-date information, leading to smarter decision-making, improved efficiency, and reduced manual errors.

BETs WMS Integration Compatibility

1. Multilevel Warehouse Integration

- Real-time synchronization of inventory data across multiple warehouse locations.

- Optimized picking, packing, and shipping processes across all warehouses.

- Streamlined order processing from different warehouse locations for faster fulfillment.

- Reduced operational bottlenecks with seamless coordination between warehouses.

- Improved visibility of stock movements and availability across multiple sites.

2. BETs Platforms Integration

- Seamless data flow between BETs Warehouse Management System (WMS) and other BETs platforms like ERP, SFA-DMS, FMS, E-commerce, Logistics, etc.

- Connected workflows for managing order processing, inventory, sales, and distribution.

- Centralized business insights and analytics across multiple BETs platforms.

- Enhanced workflow automation, minimizing manual data entry and errors.

- Greater control and oversight of operations, enabling smarter business decisions.

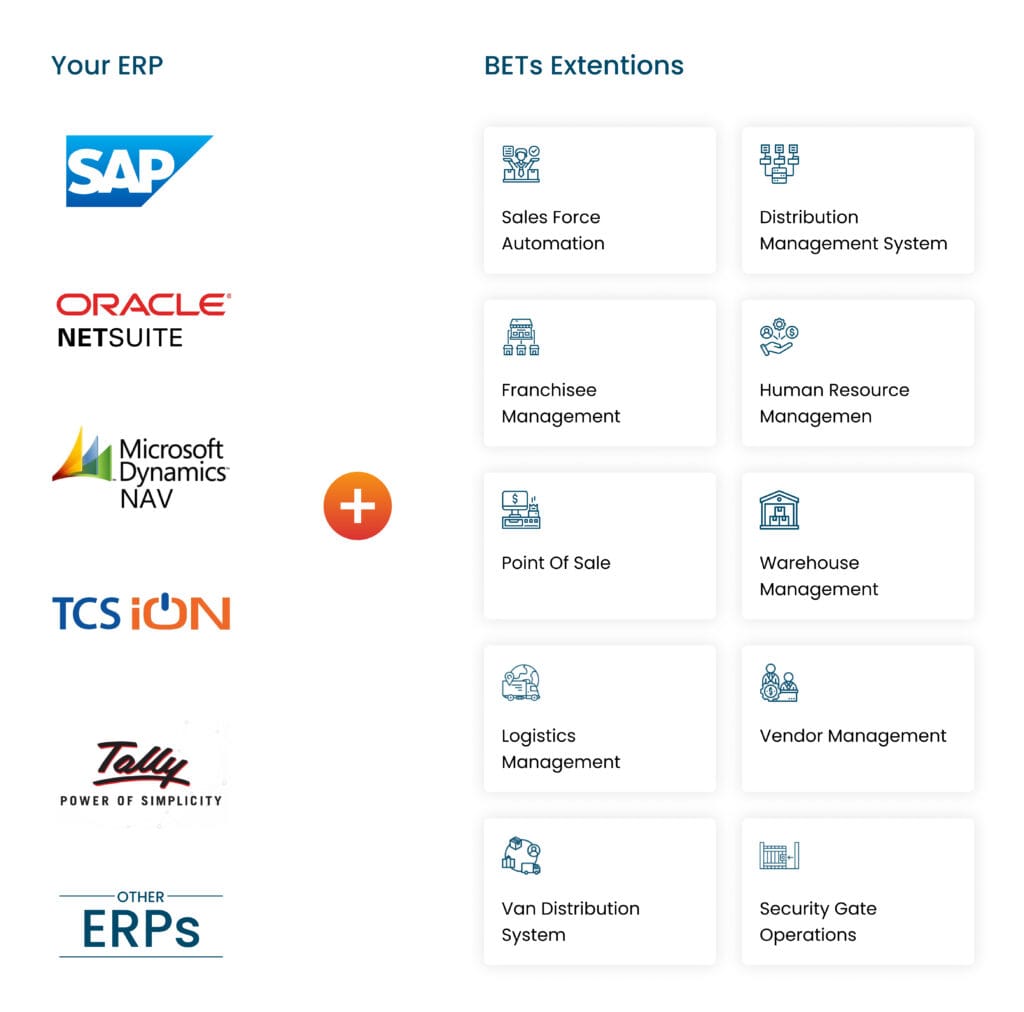

3. ERP Integrations with Leading Platforms

- BETs WMS integrates with popular ERP systems such as SAP, NetSuite, Oracle, TCS ION, Tally, and Microsoft Dynamics.

- Synchronized inventory data between WMS and ERP platforms for real-time stock updates.

- Streamlined order processing and invoicing across different ERP and WMS systems.

- Easy synchronization of accounting, finance, and reporting functions for better financial management.

- Simplified integration with existing business infrastructure, minimizing disruptions and maximizing operational efficiency.

Benefits of BETs Mobile App-Based WMS:

1. Accurate Put Away & Pickup:

BETs Mobile WMS streamlines warehouse operations with automated put-away and pickup processes. It ensures items are stored in optimal locations and retrieved efficiently, reducing errors and saving time. By automating repetitive tasks and optimizing workflows, the Mobile WMS significantly improves operational efficiency. Employees can focus on high-value tasks while the system handles routine processes.

2. Accuracy in Inventory Mapping:

The system uses barcode and RFID technology to provide real-time, precise inventory mapping. This minimizes stock discrepancies, enhances FIFO/LIFO compliance, and reduces the risks of expirations or rejections. Automation minimizes errors, reduces waste, and optimizes resource utilization, leading to substantial cost savings. Additionally, advanced analytics enable businesses to identify areas for further cost reductions.

3. Task Allocation & Tracking for All Employees:

BETs mobile WMS allows managers to assign tasks to employees through the mobile app and monitor progress in real-time. This improves accountability, boosts productivity, and ensures efficient use of resources across the warehouse.

4. Improved Accuracy

With features like barcode scanning and real-time data updates, the system ensures high levels of accuracy in inventory management and order fulfillment. This reduces errors, improves customer satisfaction, and strengthens your reputation.

5. Data-Driven Insights

The WMS generates detailed reports and dashboards, offering valuable insights into operations. Businesses can analyze performance metrics, identify trends, and make informed decisions to stay ahead of the competition.

The Future of Warehouse Management

As businesses strive to meet increasing customer demands and navigate complex supply chains, warehouse automation will play a pivotal role in driving success. BETs Mobile WMS represents the future of warehouse management, providing a comprehensive solution that combines cutting-edge technology with practical features.

By adopting this innovative platform, businesses can transform their warehouses into smart, efficient hubs that support growth and innovation. Whether you’re looking to reduce costs, enhance productivity, or improve customer satisfaction, BETs’ Mobile WMS is the solution you need to stay competitive in today’s dynamic market.

Conclusion

Warehouse 4.0 is not just a concept; it’s a reality brought to life by BETs’ Mobile App-Based WMS. With features like auto put-away and pickup lists, barcode-based material handling, and movement optimization, the platform empowers businesses to achieve new levels of efficiency and accuracy. As supply chains become more complex, investing in a robust WMS is no longer optional—it’s essential. Embrace the future with BETs and transform your warehouse operations today.